What Is a Pry Bar and What Are They Used For?

- Jun 8, 2020

Pry bars, also known as crowbars or pinch bars, are hand tools used to pull two objects apart. Their angled, flattened end acts as a lever, allowing you to apply a significant amount of force between objects. Generally constructed of steel, these durable, reliable, and multi-purposed bars are often the right tool for any construction job.

Applications for a pry bar include:

- Removing molding;

- Removing nails;

- Opening stuck windows;

- Opening a can of paint;

- Removing floor tiling;

- Reupholstering furniture;

- Puncturing glass;

- Opening a jammed car door.

Tips for Choosing the Right Pry Bar

Whether you’re a professional contractor or an avid DIY-er, choosing the best tool for the job is essential. Three matters you may want to consider when purchasing a pry bar are the brand, what materials they are made with, and their price range.

Brand

Always make sure you’re purchasing tools from a reliable, reputable brand. This way you know you are receiving a great product, supporting a business you like, and leaving channels open for later purchases.

Materials

Consider what kind of materials the tools are made of. You’ll want to choose tools made of high-quality and durable materials. Look for high-carbon steel construction for maximum durability. It’s also suggested that you select tools that are easy to maintain. Tools made of iron are prone to rust, which can cause problems down the road and the rusting nature of iron can make cleaning your tools more difficult.

Price

Lastly, you want to consider the price of the pry bar you’re purchasing. Higher-priced tools are often simultaneously made with higher-quality material for a better and more durable performance, and last longer than their inexpensive counterparts. Each purchase of a tool can be thought of as an investment that will pay off over time. When purchasing a tool from Spec Ops, you’re also putting that investment into charitable causes. With every purchase made, we give back 3% to support veteran and first responder causes.

Types of Pry Bars

There are many types of pry bars, all of which come in various shapes and sizes. Each pry bar serves its own purpose, so it’s important to know which one suits your needs best. Below are eight different pry bars to consider:

Alignment Pry Bar

Alignment bars, also referred to as sleeve bars, are among the longest and heaviest of pry bars. These bars are primarily designed to align bolt holes and other mating holes in construction and engineering. They prevent structural instability by prying the holes into alignment. However, alignment bars can also act as levers, helping users perform light lifting tasks.

The bar features one chiseled end and one pencil point tip end. Like other bars, alignment bars are made of steel.

Cat’s Claw Pry Bar

Cat’s claw pry bars, more simply known as “claw bars,” are designed primarily for removing embedded or headless nails from wood or other materials. Claw bars can typically damage the material surrounding the nail so it’s important they’re only used on surfaces where damage is expected. However, claw bars designed with precision in mind cause minimal damage to areas surrounding the nail.

One end of the claw bar features a curved claw with beveled edges, designed to slide under the head of the nail. Upon applying pressure, the nail lifts and is removed from the material. The other end of the bar typically features a simple beveled edge, a secondary claw, or a rubber grip. These bars are lightweight and extremely durable.

Digging Pry Bar

Digging pry bars are long, straight bars made of metal. These bars are used for digging and loosening hard or compacted materials such as rock, soil, tree roots, concrete, or ice. Like other bars, they can also act as a lever — though this is not their main usage. They can also be used for making holes in the ground for fence posts.

Each end of the tool is generally different to allow for two tools in one. The ends can either be blunted, pointed, chiseled, or wedged in design. For instance, the chisel end can help break apart tree roots, while a pointed end can break apart hard construction materials.

Flat Pry Bar

Flat pry bars are ideal for prying, scraping, and pulling. They can remove nails, plywood, and clapboard siding. Though they are not always as effective at removing embedded nails like claw bars are, they can still remove all types of nails. Flat pry bars have beveled edges with nail slots at both ends and a curved rocker head for maximum prying power. Like other pry bars, these are made with steel to ensure maximum durability.

Gooseneck Pry Bar

Gooseneck pry bars offer another option for nail-pulling, prying, and wrecking. The gooseneck design provides for extra prying leverage. One end features a nail pulling claw, while the other features a chisel end.

Heavy-Duty Pry Bar

Heavy-duty pry bars feature a handle with a built-in strike cap. These caps are designed to be hit with a hammer, providing extra strength and leverage support. Heavy-duty pry bars can be used to position or reposition engines, equipment, or other types of machinery, align heavy steel plates or panels, and pry heavy objects, such as decking or grates.

Molding Pry Bar

Made of carbon steel, molding pry bars are highly durable. These tools also offer versatility, as they are designed with two nail pullers. The prying-end of the molding bar is notably thin and wide, making it more useful than a flat bar at getting behind a piece of trim and less likely to cause damage.

Rolling Head Pry Bar

Rolling head pry bars are used on many jobsites. With a rolling head hook end, these bars deliver the leverage needed to pry objects apart effectively. These can also be used to align holes or for positioning parts of a machine for an accurate assembly.

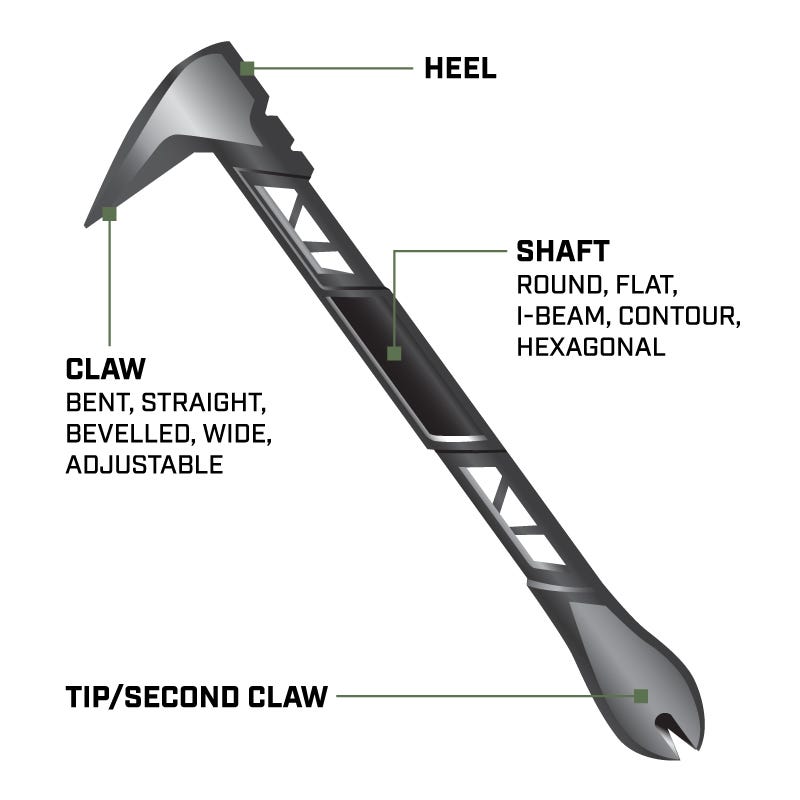

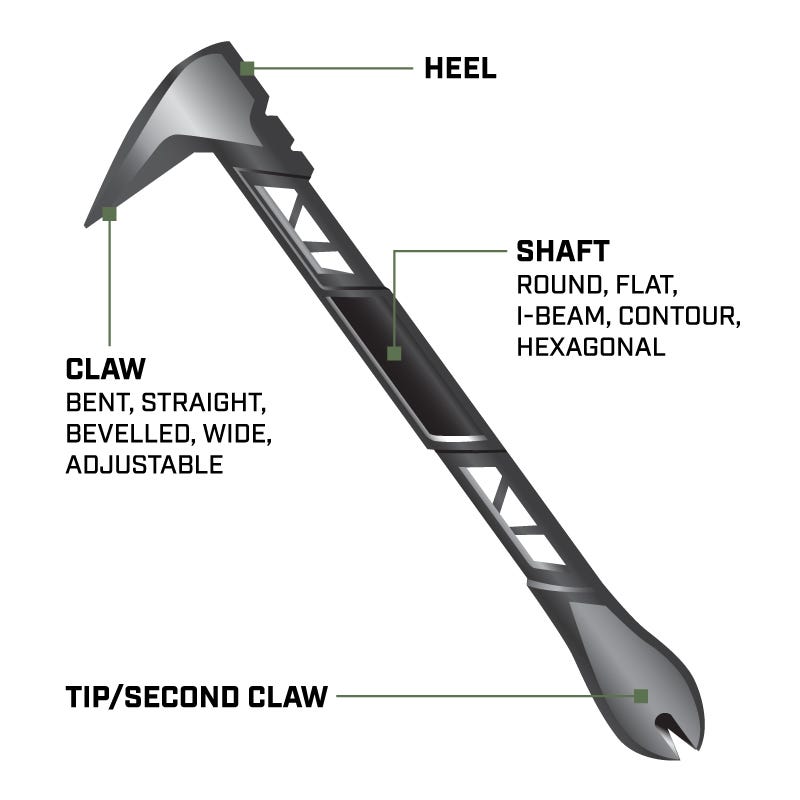

Parts of a Pry Bar